In the garment manufacturing industry, Tagless printing has gained significant popularity as an efficient and cost-effective method for labeling clothing items. Traditionally, clothing items are labeled with fabric tags that can be uncomfortable, itchy, and prone to wear and tear. Tagless printing, also known as neck label printing, eliminates the need for fabric tags by directly printing labels onto the garment. This method offers several advantages, including increased comfort for the wearer, enhanced brand presentation, improved durability, and cost savings for manufacturers.

To meet the growing demand for Tagless printing solutions in Bangladesh, a range of specially designed pad printing machines have emerged in the market. These machines offer precise and high-quality printing, ensuring clear and durable labels without the need for traditional fabric tags. Our pad printing machines offer precise control over ink deposition, enabling high-quality prints with sharp details and vibrant colors. These machines give best results when used with sure pads, preciteel cliches plates & Farbatex . Oeko level 3 certified Tagless printing inks.

|

Specially Designed Machines for BangladeshBangladesh's garment industry is renowned globally, and it requires specific solutions tailored to its unique requirements. With our experience of 35+ years we have recognized this need and developed machines specifically designed for the Bangladeshi market. These machines offer features and capabilities that address the challenges faced by garment manufacturers in the country. |

|

High-Speed PrintingEfficiency and productivity are crucial in the fast-paced garment industry. Specially designed pad printing machines for Bangladesh are equipped with high-speed printing capabilities. They can quickly and accurately apply labels to a large volume of garments, meeting the industry's demanding production targets. |

|

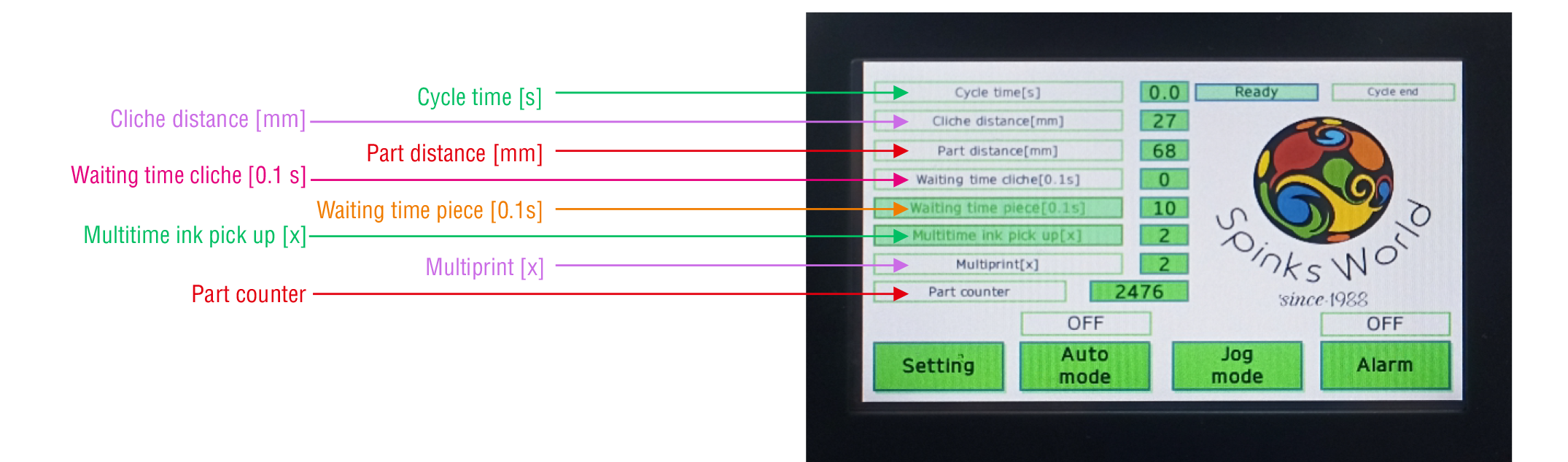

Customization OptionsGarment manufacturers often require the flexibility to customize labels based on different product lines,

sizes, or designs. The specially designed pad printing machines offer customizable settings, allowing

for easy adjustment of label designs, font sizes, and positioning. This versatility in our HMI, enables

manufacturers to meet their diverse labeling requirements efficiently. |

|

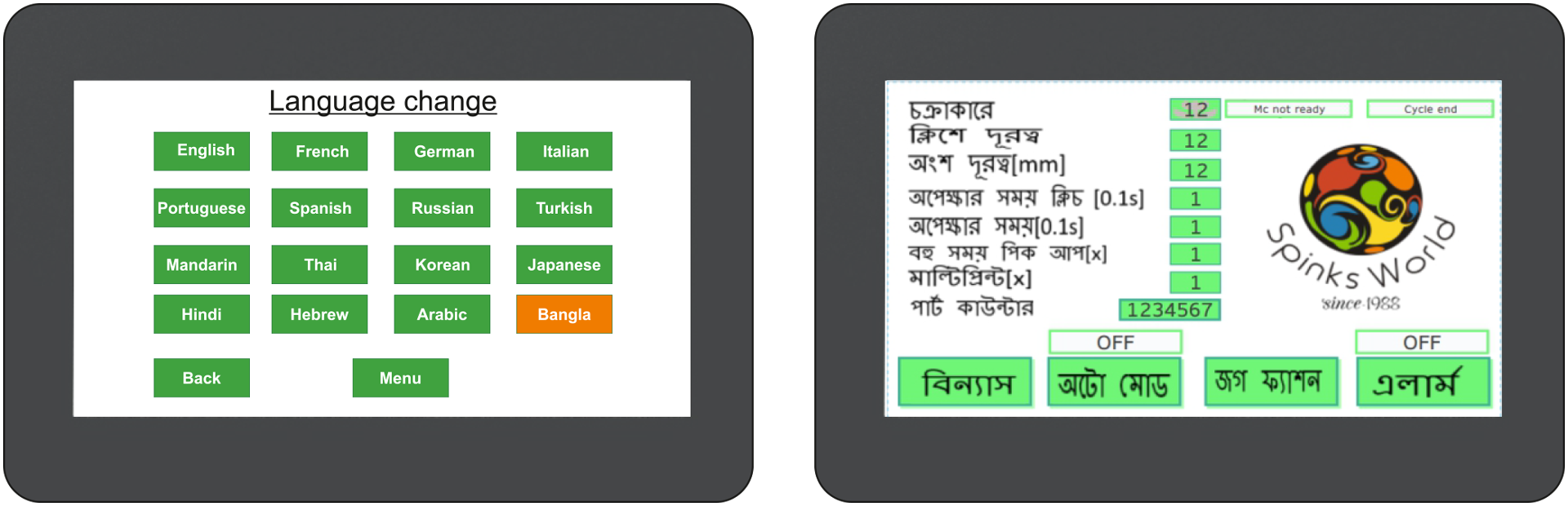

User-Friendly OperationSimplicity & ease of use are essential for efficient production processes. The pad printing machines designed for Bangladesh prioritize user-friendly operation. These machines have Bangla as an option for language in the interface, which makes it easy-to-understand controls, & automated functions to streamline printing operations. This user-centric design helps minimize downtime, reduce training requirements, and optimize overall productivity |

|

Durability & ReliabilityIn an industry with high production volumes & tight deadlines, machine reliability is paramount. The specially designed pad printing machines are built to withstand the rigors of continuous operation. They are constructed using durable materials, incorporate robust components, and undergo rigorous quality control measures. This ensures long-lasting performance, minimal maintenance, and maximum uptime for garment manufacturers in Bangladesh. |

|

Cost-Effectiveness“BRAND QUALITY AT FAIR PRICE” Cost-effectiveness is a crucial consideration for any business. Pad printing machines for tagless printing in Bangladesh offer significant cost savings compared to traditional fabric tag labeling methods. The elimination of fabric tags reduces material costs, while the efficiency of pad printing machines reduces labor requirements. Moreover, the precise ink deposition minimizes ink wastage, contributing to further cost savings. |

Conclusion

Pad printing machines for tagless printing have revolutionized the garment labeling process, providing comfort, durability, and branding advantages. Specially designed machines for Bangladesh's garment industry offer high-speed printing, customization options, user-friendly operation, durability, reliability, and cost-effectiveness. By embracing these advanced printing solutions, garment manufacturers in Bangladesh can streamline their production processes, enhance the quality of their products, and cater to the growing global demand for tagless garments.

FAQs

| 1. Are pad printing machines suitable for all types of fabrics? |

|

Yes, pad printing machines can be used on various fabric types, including cotton, polyester, blends, and more. However, it is essential to test the compatibility of the ink and fabric to achieve optimal results. |

| 2. Can pad printing machines print multiple colors? |

|

Yes, pad printing machines can accommodate multi-color printing. We have 2/3/4/5/6 color options available for multicolor pad printing. |

| 3. What is the maintenance requirement for pad printing machines? |

|

Pad printing machines require regular cleaning and maintenance to ensure consistent performance. The maintenance procedures are usually straightforward and provided by the machine manufacturer. |

| 4. Can pad printing machines be integrated into existing production lines? |

|

Yes, pad printing machines can be integrated into existing garment production lines. They can be configured to work seamlessly with other machinery, allowing for efficient and continuous printing processes. |

| 5. Where can I find pad printing machines for tagless printing in Bangladesh? |

|

We offers pad printing machines in Bangladesh. Please contact us for your tagless printing requirement. |

| 6. Where can I get tagless printing machine service in Bangladesh? |

|

We offers service and repairs of tagless printing machines. |

| 7. Where can I get tagless printing inks in Bangladesh? |

|

We offers oekotex certified tagless printing inks for garments |

| 8. Where can I get pad printing plates and silicone printing pad for tagless printing in Bangladesh? |

|

We offers laser etched pad printing cliche plates and different types of silicone pads for tagless printing in Bangladesh. |

Tagless ® is a registered trademark of HBI Branded Apparel Limited, Inc.