Complete solutions provider of Tagless Printing.

Request for more information

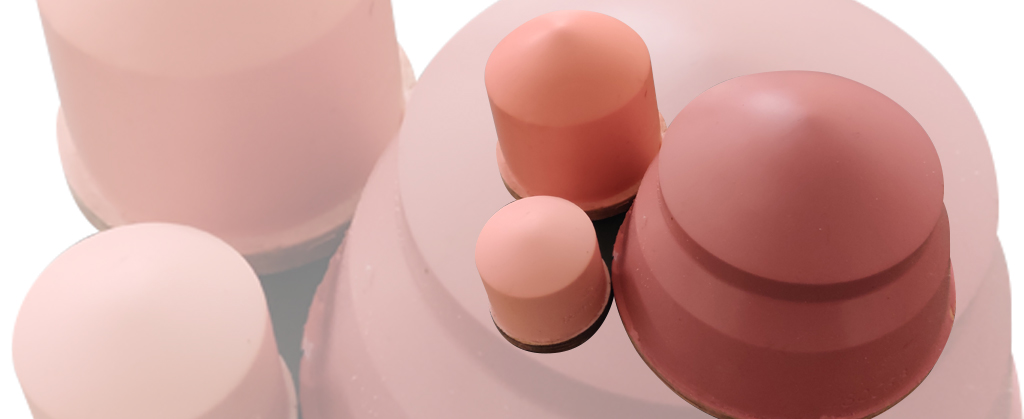

Tagless Pads/  Silicone Printing Pads

Silicone Printing Pads

Today in pad printing, transfer pads made

from silicone rubber are used almost exclusively since the silicone materials

are the best known release agents for this printing process.

The tagless neck label Printing Pads are made with special silicone rubber with following characteristics :

- Excellent absorption and detachment of the ink; perfect transposal of the image to be printed.

- High tear strength and resistance to solvents and inks, long pad life

- Hardness and form stability; possibility of being used several times

- Easy to be cleaned; quick maintenance.

Elements effecting the choice of the tagless neck label Printing Pads:

- Dimension of the printing surface: printing area

- Type of printing surface: smooth, rough, etc.

- Number of the colours to be printed.

Important about tagless neck label printing Pads:

- For rough surfaces it is recommended to use soft pads of 2-8 Shore hardness .

- The size of the pad depends on the printing surface.

- Pads with dimensions at least 20% greater than the printing area are necessary.

- The data of the pads listed in this catalogue refer to the maximum printing possibility.

- Some commonly used pads - 60/90/130.

FT series tagless neck label printing SURE pad models:

- SURE -FT A series pad model:

- 440-60A

- SURE -FT B series Pads model:

- 465-60B

- 394-90B

- 448-130B